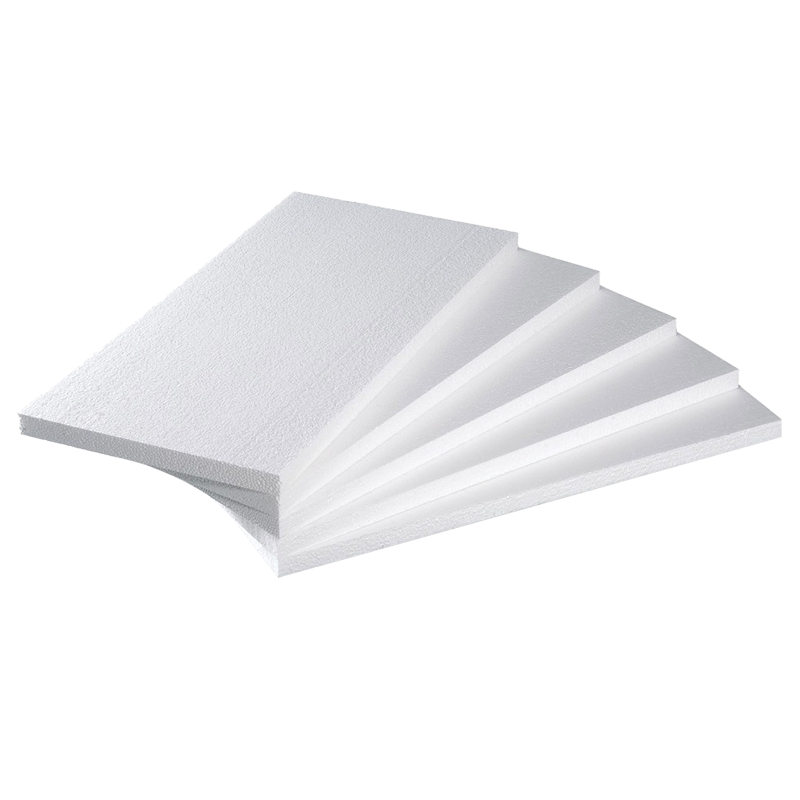

PEBA Foam Sheet is a groundbreaking material shaping the way technology and design converge, making it an indispensable component of advanced applications. Its exceptional impact resistance, thermal stability, and chemical resistance make it ideal for a range of different industries and applications. Moreover, it is also highly durable and can withstand diverse environmental conditions. In addition to these outstanding properties, PEBA Foam Sheet is also extremely lightweight, allowing for easier handling, transportation, and installation, as well as contributing to reduced fuel efficiency and enhanced sustainability. PEBA was brought onto the market by Evonik more than 40 years ago and is used extensively in sporting goods, particularly running shoes. Its cold impact strength, chemical resistance, high elasticity and resilience are valued by leading footwear manufacturers.

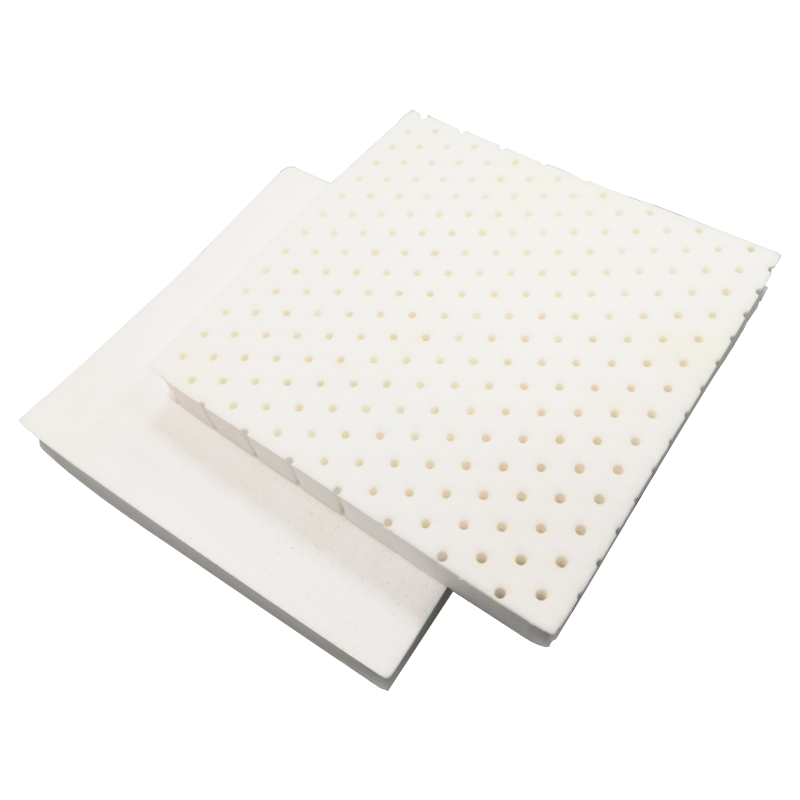

Its unique structure makes it able to absorb and disperse impact energy, preventing the transfer of force from the foot to the shoe, which could damage its components or cause injury to the wearer. Furthermore, its closed-cell foam structure offers a high degree of flexibility that allows it to bend and stretch without losing integrity or compromising performance. PEBA Foam Sheet is also resistant to moisture, sunlight, and extreme temperatures, ensuring that its products are long-lasting and durable.

Another advantage of PEBA is its ability to withstand repeated impacts, making it ideal for sports shoes that need to withstand frequent contact and abuse. The material also has excellent mechanical properties, including tensile strength and compressive modulus. In addition, it is easy to work with and has excellent surface hardness. This makes it an ideal choice for footwear with high requirements on durability, aesthetics, and comfort.

In recent years, PEBA has become increasingly popular as a material for running shoes, thanks to its superior rebound and energy return. It has a higher rebound than any standard EVA and is more resilient to compression, allowing for a greater number of joules, or energy units, to be stored and then returned during use.

As a result, PEBA provides a much more comfortable and efficient running experience than traditional EVA foams. This improved energy return helps to reduce muscle soreness and fatigue after a workout or long run, and is particularly helpful for runners with knee issues.

PEBA is also a lighter material than standard EVA, and it is up to 28% lighter than Nike's Boost, which is the best-performing standard foam on the market. As a result, it is suitable for heavier runners and those with above-average foot volume.

PEBAs are also well suited for overmolding, a technique in which a layer of the material is injected into an insert. The cohesion of the two materials is achieved through the properties of hot melt and compatibility of the overmoulded material and the insert. In addition, PEBAs have a wide range of plasticization, which allows them to optimize the adhesion between the overmoulded material and insert, as well as to avoid the use of adhesive. This is a key advantage over other TPEs, such as PE, which have poor direct adhesion to most substrates.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229