Home / News / Biodegradability of M-TPEE Foam Sheet: Characteristics, Analysis and Challenges

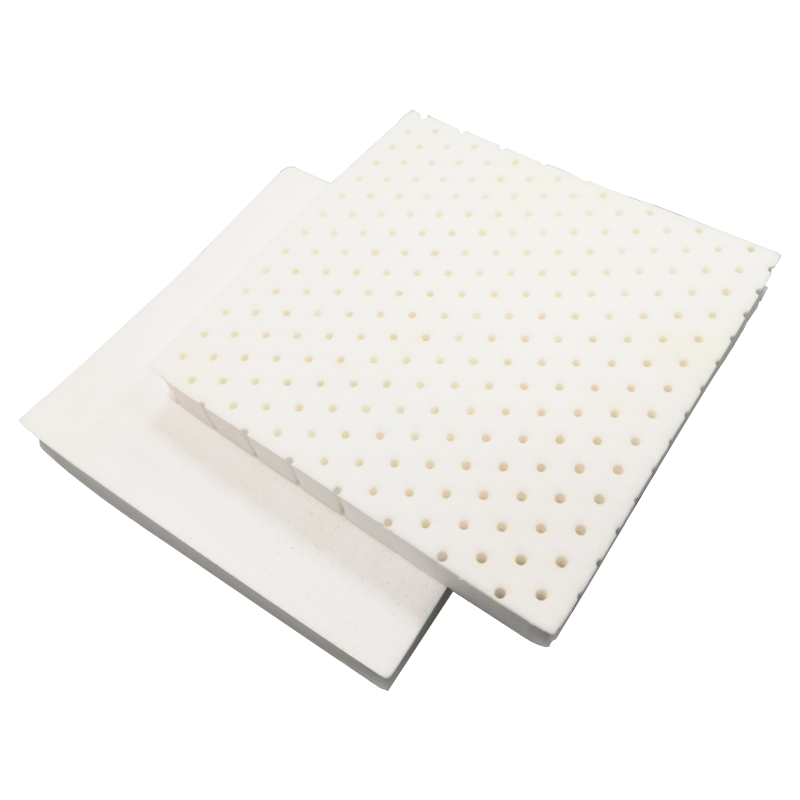

1. Basic Characteristics of M-TPEE Foam Sheet

M-TPEE Foam Sheet is a thermoplastic elastomer foam sheet composed of polyester polyols, diacids and succinates. It combines the processability of thermoplastics with the elasticity of elastomers, and has excellent wear resistance, oil resistance, chemical resistance and high temperature resistance. These characteristics make M-TPEE Foam Sheet widely used in the fields of automobiles, electrical electronics, medical devices, toys and sports equipment.

2. Basic Concept of Biodegradability

Biodegradability refers to the property that a material can be decomposed into small molecules or low molecular weight compounds such as carbon dioxide and water by microorganisms (such as bacteria, fungi, etc.) through biochemical action under natural environmental conditions. This process involves the attack and decomposition of polymer materials by microorganisms, and the further metabolism of decomposition products by microorganisms.

3. Biodegradability Analysis of M-TPEE Foam Sheet

Influence of Chemical Structure:

The chemical structure of M-TPEE Foam Sheet has an important influence on its biodegradability. Thermoplastic polyester elastomers usually contain ester bonds, which are easily broken by microorganisms, thus initiating the degradation of the entire molecule. Other chemical structures in M-TPEE Foam Sheet, such as aromatic or aliphatic groups, may affect the accessibility of ester bonds and the degradation rate.

Effect of Molecular Weight and Crystallinity:

The molecular weight of a polymer has a significant effect on its biodegradability. Generally speaking, polymers with lower molecular weights are more easily degraded by microorganisms. M-TPEE Foam Sheet has a wide molecular weight distribution range, and its biodegradability may vary depending on the molecular weight. Crystallinity also affects the biodegradability of M-TPEE Foam Sheet. Amorphous structures are more easily degraded by microorganisms than crystalline structures because the amorphous regions have loose chain structures that are conducive to the growth of microorganisms and the action of enzymes.

Effect of Additives:

Various additives, such as plasticizers, stabilizers, etc., may be added to M-TPEE Foam Sheet during the production process. These additives may affect its biodegradability. Some additives may accelerate the degradation of polymers, while others may inhibit the degradation process. When evaluating the biodegradability of M-TPEE Foam Sheet, the type and content of additives need to be considered.

Impact of environmental conditions:

Environmental conditions such as temperature, humidity, oxygen concentration and pH value can also affect the biodegradability of M-TPEE Foam Sheet. Higher temperature and humidity are conducive to the growth of microorganisms and the activity of enzymes, thereby accelerating the biodegradation process. In actual environments, these conditions may vary depending on factors such as geographical location, season and climate.

4. Challenges and opportunities of biodegradability of M-TPEE Foam Sheet

Challenges:

Cost issues: The cost of biodegradable plastics is generally higher than that of traditional plastics, which limits their market promotion and application.

Degradation rate control: The biodegradation rate of M-TPEE Foam Sheet may vary depending on factors such as chemical structure, molecular weight, additives and environmental conditions, and it is difficult to accurately control.

Recycling and treatment: Although M-TPEE Foam Sheet is thermoplastic and can be recycled and reused, in actual applications, the recycling and treatment system is still imperfect.

Opportunities:

Promotion of environmental protection policies: With the increasing global attention to environmental issues, governments of various countries have introduced relevant policies to promote the research and development and application of biodegradable plastics.

Technological innovation: Through optimizing chemical structure, improving biodegradability, reducing costs and other technological innovations, the application of M-TPEE Foam Sheet in the field of biodegradable plastics can be promoted.

Market demand growth: With the growing demand of consumers for environmentally friendly products, the market prospects of biodegradable plastics such as M-TPEE Foam Sheet are broad.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229