Home / News / PEBA Foam Sheet for Midsole and Forepart Insert Applications

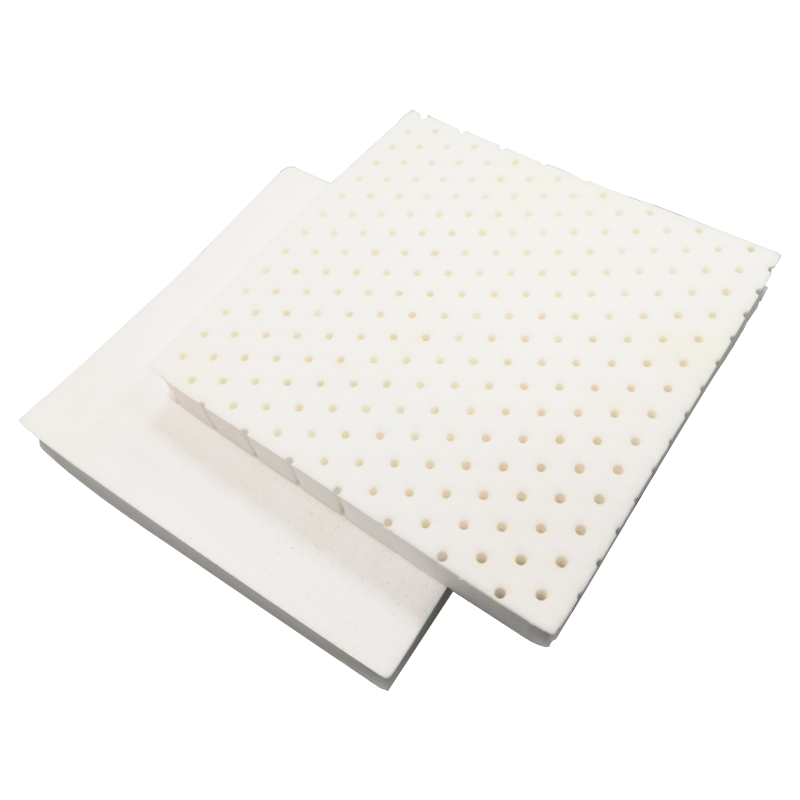

Developed by Huntsman, in conjunction with Shincell New Material Company Ltd, PEBA Foam Sheet is being used in a range of midsole and forepart insert applications across some of the world’s leading footwear brands. It is produced by spraying a mixture of solvent-free and water-free TPU resins onto aluminium foil, which is then heated, resulting in the TPU resins melting and expanding. This expansion forms the TPU foam, which is then cut into various sizes and shapes to be used in footwear applications.

TPU Foam Sheet is a very durable and highly pliable material that allows for a great deal of flexibility, providing cushioning and energy return. It is also a lightweight and very strong material, which is very easy to work with and is therefore ideal for shoe manufacturers looking to reduce production costs by using lighter materials. TPU Foam Sheet can be moulded into complex and curved shapes, as well as cut into different shapes, making it perfect for the production of footwear products.

It is also very clean to bond TPU Foam Sheet with different materials, which is very essential for shoe production, allowing the introduction of modern and thrilling products that might not be feasible without it. This is made possible thanks to the houses of TPU Foam Sheet, which allow it to bond with different materials such as rubber, leather-based, and fabric. TPU Foam Sheet can be bonded to other substances by the use of warmth, a chemical, or by the use of an adhesive.

The cloth is a polyether block amide, which Arkema calls Pebax, which offers it a completely unique set of characteristics, including excessive resilience, a low durometer (a measure of the cloth hardness), and a fantastic feeling of “rebound”. Pebax is likewise very light and sturdy.

Like Lego, Pebax is manufactured from blocks, each with an exclusive hardness or softness, each of which may be adjusted to provide the favored houses. The distinctive lengths of the tough and tender blocks mean that Arkema can create particular homes which include rebound, durability, abrasion resistance, or moisture permeability.

As a result of the way it is manufactured, Pebax has a number of benefits over other TPEs, such as true anxiety a low density, and a completely low bloodless stiffening. This makes it very suitable to be used in jogging shoes.

For instance, it may be furnished as a breathable, antistatic, or as bio-primarily based product with the use of Pebax Renew. Both kinds are aerated with the usage of progressive MuCell extrusion generation, and it's miles to be had in various shades and as a breathable foam with or without nitrogen saturation. It is also UV stable and can be ozone resistant.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229