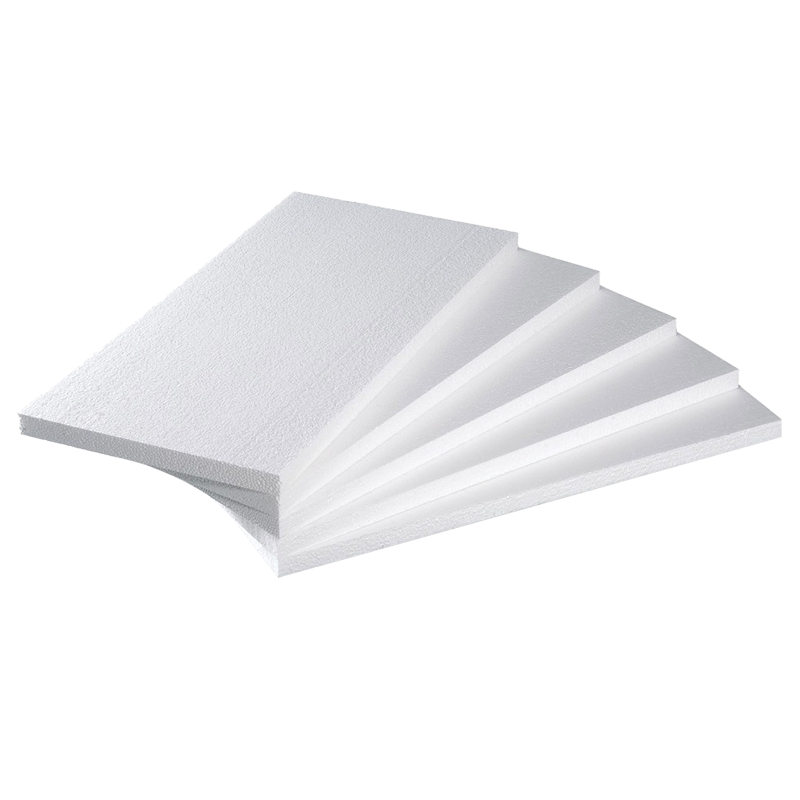

Polypropylene (PP) is a closed-cell foam that offers multiple benefits like thermal insulation, buoyancy and protection. Its diverse features have made it a popular choice for shipping and constructions. It is a versatile material that can be produced in a variety of shapes & sizes depending on customization & orders.

PP foam is created by a critical and complex producing procedure. It requires high-end equipment and highly precise customization material operated by expert technicians. The result is a material that is durable, lightweight and aesthetically pleasing. It is also available in a variety of colors and can be molded into many different shapes.

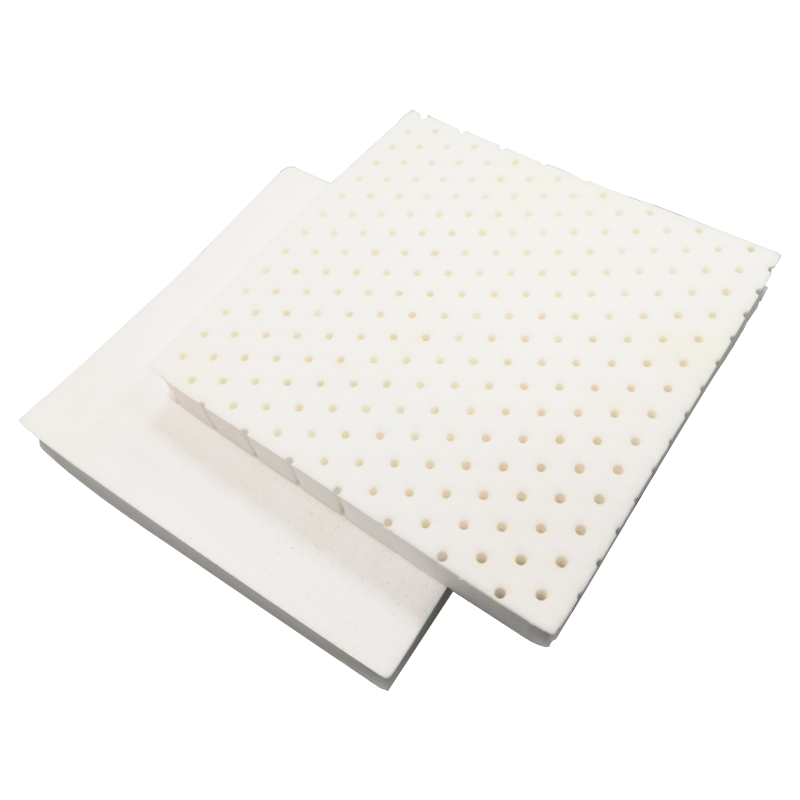

The process of making PP Foam Sheet involves extruding a high melt strength, high melt elasticity polypropylene characterized by high Mz value and/or high Mz/Mw ratio. The temperature and pressure of the melt and the screw speed are controlled to optimal values. The molten foaming mixture is pumped through the die at 325deg F. The resulting foam sheet has smooth surfaces with uniform cell size and microstructure. The foam sheet also has high tensile and flexural moduli and low cell density.

Polypropylene resins that yield acceptable foam sheets, according to the invention, have equilibrium compliance Jeo values above 12x10-5 cm2 /dyne. Resins with Jeo values below this limit yield unacceptable foam sheets that have non-uniform cell structure and rough surfaces.

During the production of PP foam sheets, the average cell size is determined by scanning electron microscopy (SEM). The SEM image reveals the dimensions and shape of each individual cell. The average cell diameters are measured in the machine and cross machine directions.

In addition to the properties mentioned above, a PP Foam Sheet is also resistant to corrosion and moisture. This is because it is coated with a layer of ethylene vinyl acetate. The coating is also anti-microbial. This ensures that the foam will retain its quality and appearance for a long time.

Another reason that a PP Foam Sheet is so popular is its ability to be molded into a wide variety of shapes. This versatility makes it a great material for manufacturing consumer products, such as children’s toys and furniture. It is also a good material for packaging because it is very lightweight and can withstand a lot of stress.

Moreover, a PP Foam Sheet is easy to handle and transport. It is also lightweight, which means it is easier to ship and more cost effective than heavier materials. This is a big benefit for distributors who need to deliver products safely. It also offers excellent acoustic insulation, which protects products from vibrations and sounds. This is why it is a great choice for shipping delicate items. This is a major advantage for online retailers who need to protect their products from the elements and other external factors. It is also a great option for warehouses that need to keep their inventory in safe conditions for a prolonged period of time. This way, they can prevent damage and keep their customers happy.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229