Home / News / PVDF Foam Sheet is an unreinforced semi-crystalline thermoplastic fluoropolymer material

PVDF Foam Sheet is an unreinforced semi-crystalline thermoplastic fluoropolymer material with great mechanical and thermal properties, in addition to excellent chemical resistance. As an engineering material, it finds application in applications such as electrical wire insulation, medical packings, anti-corrosion linings, and slide parts linings. Furthermore, it has a wide temperature range, high purity status and is FDA-approved for food contact; while also being highly UV and radiation-resistant.

As it has an ultra-low density of 1.78 g/cm3, PFA is extremely lightweight compared to other fluoropolymers such as Polytetrafluoroethylene (PTFE, or Teflon). PFA can be easily injected, molded or welded for injection molding applications in industries including chemical processing, pharmaceutical, semiconductor fabrication and defense applications - including lithium-ion batteries. Furthermore, closed-cell foam products made of PFA are available specifically for aerospace use.

PVDF is an exceptionally durable material with low permeability that resists most chemicals, as well as being impact-resistant and vibration resistant. Due to this feature, it is often employed in applications requiring high levels of purity such as solvent resistance or alkali corrosion resistance; such applications include protecting vessel exteriors and providing premium wire insulation insulation.

PVD (Polyvinylidene Difluoride) belongs to a class of materials known as fluoropolymers that contain carbon-fluorine bonds that make them extremely slippery and easy to move with minimal coefficient of friction and an excellent dielectric constant. They're therefore extremely popular as lubricants, coatings, and sealants in high performance vehicles and industrial equipment.

PVDF plastic is an inert plastic produced through polymerization of Vinylidene Difluoride resin, used widely as protective sheathing in communications and plenum systems as well as used extensively in battery production. PVDF resin also has applications in lithium-ion battery manufacture.

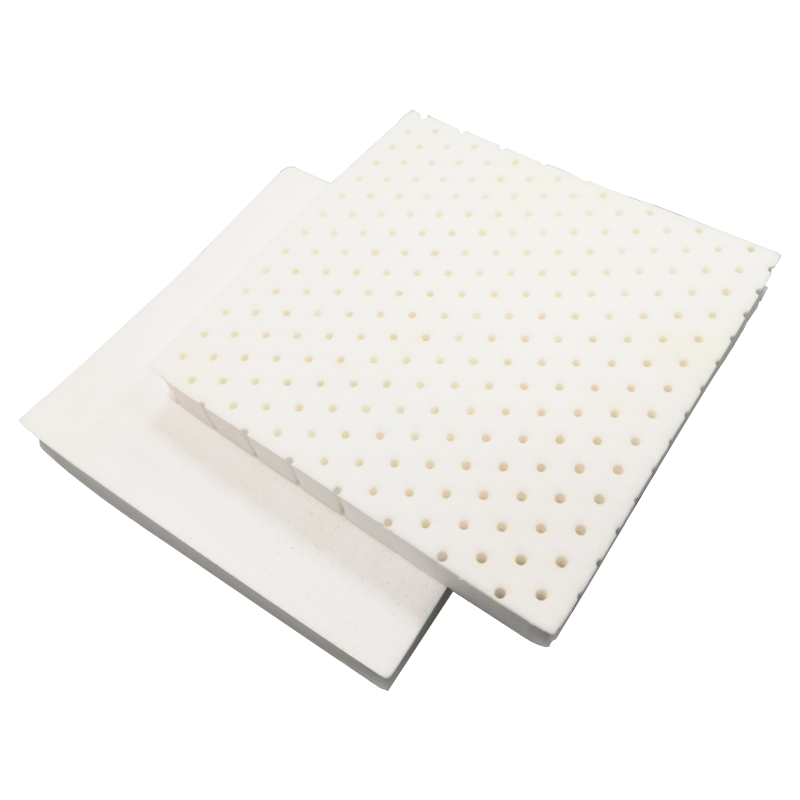

PVDF plastics have an average life of over 50 years. It can withstand impact and vibration shock as well as harsh chemical processing environments without suffering damage, as well as being highly recyclable. They boast excellent abrasion resistance, low permeability and are recyclable at every level. Pump and valve bodies, piping and tubes as well as parts exposed to chemicals or mechanical stress are made of stainless steel for this reason, making it an excellent material choice. Engineered plastic is an invaluable engineering material with an outstanding cost-benefit ratio, offering corrosion protection as well as beautiful gloss and color retention on metal surfaces. It makes an exceptional paint for metal surfaces. Grip foam is an economical alternative to more costly engineering plastics, and can be combined with them to achieve more complex or unusual designs. This provides greater design freedom with reduced weight and cost, providing better value for money. Furthermore, its thermal expansion properties allow it to be heated to higher temperatures before being reshaped - making this material easier than others to work with and shape.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229