Fitness mat includes: training mat, skipping mat and yoga mat.

Yoga postures use ancient and easy-to-master techniques to improve people's physical, psychological, emotional and spiritual state. Which is an exercise of aiming at harmony of both body and mind.

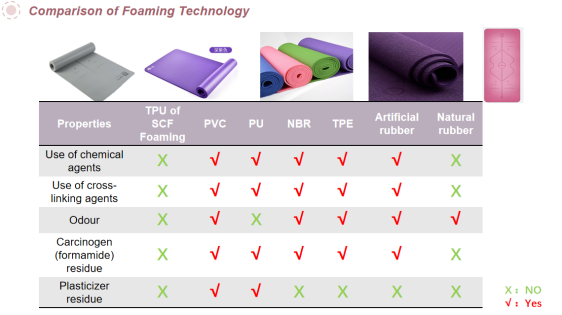

The materials traditionally used for fitness mats on the market.

1.Rubber

Good resilience, durability, and non-slip performance, but the hands and feet sweat would affect the non-slip performance. Have bad smell and hard to remove; chemical foaming with formamide residues, which are harmful to health.

2.PU Rubber

Water-absorbing and breathable, good anti-slip effect but stains easily and difficult to clean. Chemical foaming with formamide residue, which is harmful to health.

3.TPE

Good resilience, durability, and non-slip performance, but it is chemical foaming with formamide residues, which are harmful to health.

4.NBR

Good resilience, but with bad anti-slip and rebounce performance. Failure to control the calcium oxide ratio during the processing, it may cause skin allergies or burning sensation. Chemical foaming with formamide residues, which are harmful to health.

5.PVC

Gradually eliminated by the market because of its poor tear resistance and lack of elasticity and the skins will fall off easily after long use.

Why choose MTPU mat?

TPU raw granules have good wear resistance, high energy rebound, and excellent chemical resistance. TPU are widely used in various fields.

TPU is the abbreviation of thermoplastic elastomer, one of the PU catagories. With high tension, high tensile strength, toughness and aging resistance, TPU is a mature environmental friendly material.

As an elastomer, TPU SCF sheets have characteristics between that of rubber and plastic. It is oil, water, and mold-resistant. TPU products have outstanding load-bearing capacity, impact resistance and shock absorption performance. More importantly, it is 100% recyclable.

TPU belongs to the synthetic resin, and the TPU foam sheets are made by extrusion molding and supercritical fluid foaming. This material become soft under certain temperature, but remain unchanged at room temperature, acting as a stable support.

Comparison of #SCF TPU with traditional chemical foaming

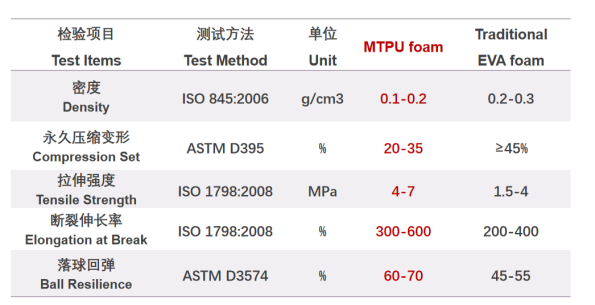

Properties of SCF TPU foam and chemical foaming EVA foam

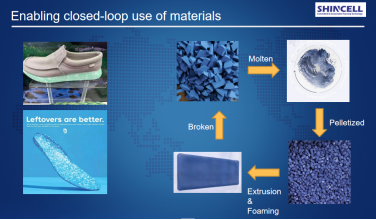

#Shincell SCF tech. makes mat production in cycle possible!

The R&D team has been focusing on the industrialization of supercritical fluid foaming technology for 20 years. With self-developed supercritical foaming process and complete sets of manufacturing equipments(patented), Shincell team won the first prize of the 2020 Shanghai Science and Technology Award.

Shincell yoga mat are produced by TPU microcellular integrated foaming (not popcorn foaming). Supercritical foaming tech (SCF). uses ONLY CO2 and N2 as the blowing agent, no chemical agents, no crosslinking. A purely physical/environmental manufacturing process!

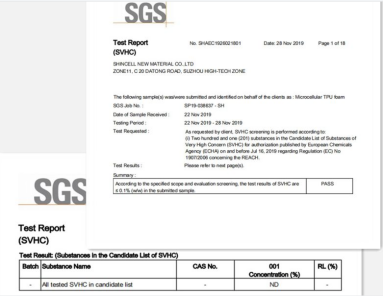

The Reach Test result of MTPU foam, none of the 201 SCHC (Substances of Very High Concern) is detected!

Shincell truly defines what is real safe!

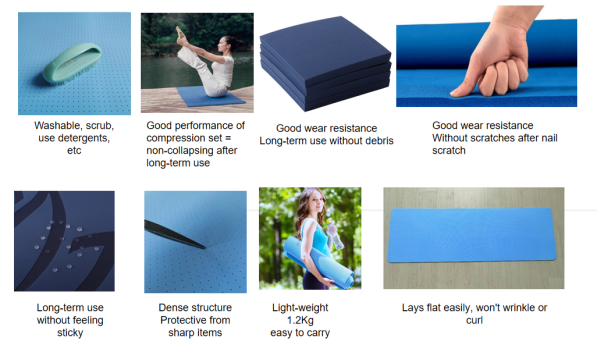

Other Merits of MTPU Yoga mat

Shincell Vision

Committed to sustainable foaming technology, Shincell is aiming to become a global leading supplier of high-performance lightweight materials and their solutions!

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229