FRPP (Fibre Reinforced Polypropylene) foam sheet materials are among the most flexible options on the market. Available in various densities and formulations, FRPP gives users endless possibilities when it comes to creating custom packaging solutions - be it electronics protection during shipment or cushioning fragile fruits and vegetables, there's sure to be something perfect to meet their individual needs.

FRPP uses a resin composed of vinyl ester or polyester thermosetting plastic combined with fibers such as glass, carbon, or aramid for creating composite material. It's often combined with epoxy, vinyl ester, or polyester thermosetting plastic resins and used to form high-performance composite products used in applications requiring corrosion resistance such as boat manufacturing, aircraft construction, and vehicle components as well as marine equipment.

FRPP boasts an exceptional strength-to-weight ratio, making it an excellent material to manufacture structural components such as beams and columns. Furthermore, this type of composite can also be used to reinforce damaged concrete structures by hand-laying up fibrous material impregnated with resin onto clean and prepared surfaces of structures.

FRPP boasts an outstanding strength-to-weight ratio and other distinctive properties that make it useful in multiple applications. For instance, its moldability allows manufacturers to produce plastic containers and furniture products; additionally, its affordable pricing and superior thermal properties make FRPP an effective insulation material.

Anti-static properties of FRPP make it an excellent way to pack delicate electronics like computers and tablets without risk of damage during shipping, ensuring they arrive at their destinations undamaged. Anti-static properties make the material even more effective by dissipating static charges to safeguard sensitive electronics from being damaged during handling and shipping.

As with other foams, FRPP comes in various forms and formulations. Depending on its intended use, additives may be added to further improve its performance - for instance, anti-static or flame retardant treatment can improve performance; physical cross-linking offers more versatility while chemically cross-linked foams tend to be stronger and harder to break apart.

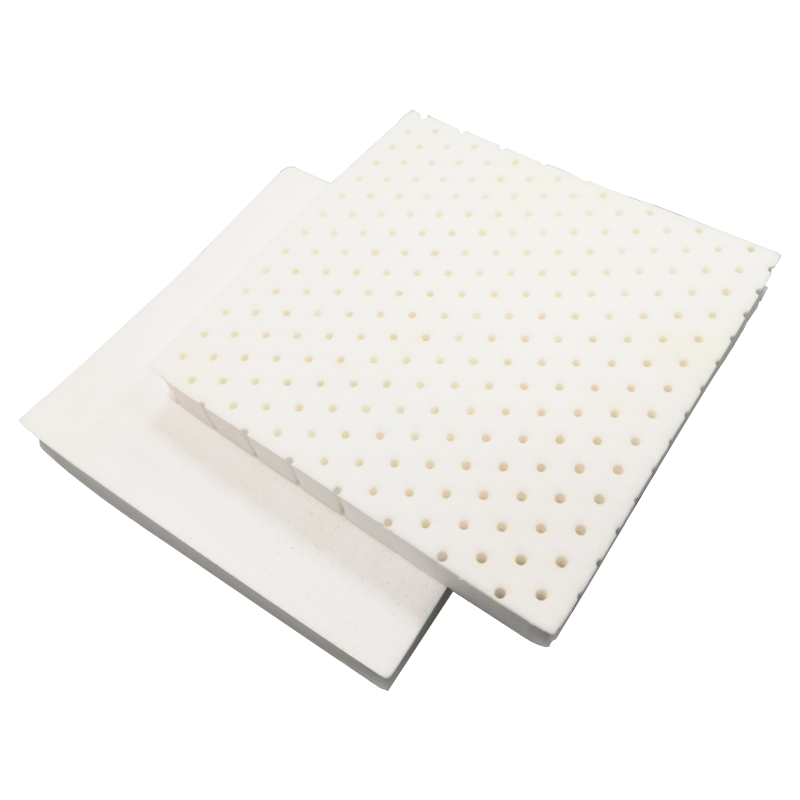

FRPP foam sheets provide an ideal way to secure delicate electronic devices or pack fragile fruits and vegetables without risking impact damage. You can cut it to fit any container, wrap objects in it, and provide excellent cushioning to absorb impact impacts while transporting. Furthermore, professional movers use it to cover furniture legs before transport and protect from scratches while wrapping furniture legs against scratches during transport. It's also great for creative projects as its flexible nature and reduced bulk makes it an excellent option.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229