Home / News / TPEE Foam Sheet - A Game-Chaner in the Packaging Market

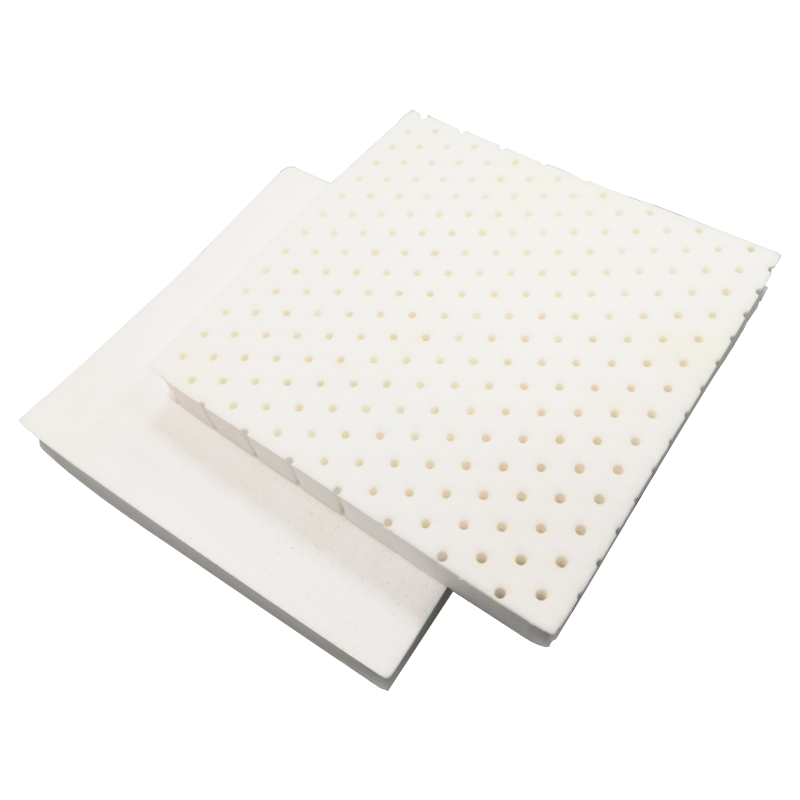

TPEE Foam Sheet is becoming the preferred material for industrial applications that require flexible, durable, and impact-resistant solutions. Its closed-cell foam structure provides a cushioning effect, absorbing and dispersing the impact energy of moving objects. This quality makes it an essential packaging material that enhances product safety during transportation and storage. It also offers good weather resistance, making it a versatile material that can be used indoors and outdoors. Moreover, it is a green alternative to traditional materials and supports sustainable manufacturing and design principles.

This new, impact-resistant material is a game-changer in the global packaging market, transforming industries through a wide range of innovative applications. Its flexible nature and customizable properties are redefining the future of packaging and other high-performance applications. TPEE Foam Sheet is also environmentally friendly, allowing it to be recycled and reused, reducing waste generation and contributing to a circular economy.

Due to its exceptional impact resistance and versatility, TPEE is an ideal material for the manufacture of packaging materials, automotive components, furniture, industrial equipment, and other products that require flexible and durable solutions. In addition, the material is recyclable and can withstand various environmental conditions, including extreme temperatures, UV radiation, and chemical exposure. This makes it an excellent alternative to other materials, including plastics and metals.

The tensile strength of TPEE is high, enabling it to hold large loads without tearing or damage. This property is the result of the cellular structure of the material, which creates a strong bond between the polymer chains. This bond is strengthened further by crosslinking with ethylene glycol (EG). In addition to this, the elastomer is resistant to degradation and has an excellent shock damping capability.

Adding PTFE fibrils to a powder slush molding composition of TPEE improves the foaming performance of the resulting material. The puffed TPEE/PTFE nanocomposites exhibit excellent expansion ratios and fine cell structures. The improved crystallization behavior of the grafts is attributed to the fact that the fibrils act not only as nucleation agents but also as a template for the spherical TPEE crystals to transform into rod-like crystals.

This change in the morphology of the crystals can be further explained by the results from a shear rheological test. As shown in Figure 10, samples with PTFE nanofibrils have much higher Hencky strain values than those of PTFE0 at all elongation rates. However, at low elongation rates, khE for PTFE0 is below 1, indicating mild strain-softening behavior. In contrast, the khE value increases with the increasing content of PTFE nanofibrils, reaching 1.25 at the highest elongation rate employed.

The kinetic parameters for the TPEE/PTFE nanocomposites were measured using the Kohlrausch-Williams-Watts model. This method combines dynamic mechanical analysis in the uniaxial tensile mode with cooling curves. The results revealed that PTFE nanofibrils promote the crystallization of TPEE, which is in agreement with the DSC analysis results. In addition, the PTFE nanofibrils increase the crystallization temperature and accelerate the crystal growth process. In terms of dimensional stability, the results from a creep recovery test in the uniaxial tensile test indicate that a branched TPEE/PTFE composite has better shrinkage behavior than the linear TPEE.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229