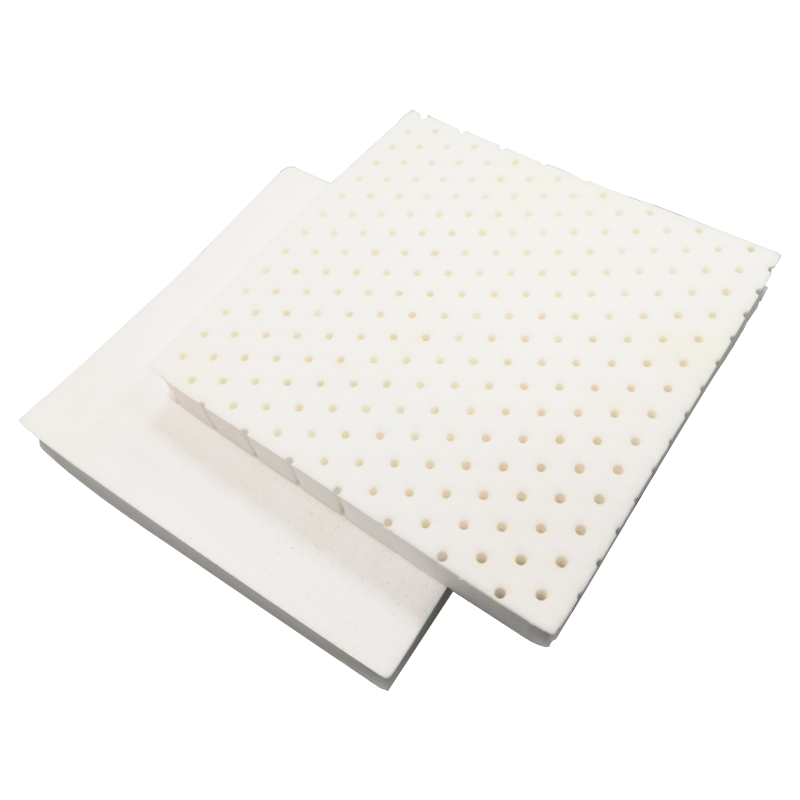

Home / News / What are the main raw materials for producing FR-MPP Foam Sheet? How is the supply of these raw materials?

The main raw materials for producing FR-MPP Foam Sheet include polypropylene (PP) resin, flame retardant and a series of additives, such as foaming agent, nucleating agent, cross-linking agent, plasticizer, etc. The selection and supply of these raw materials are crucial to the production of FR-MPP Foam Sheet.

Main raw materials

Polypropylene (PP) resin

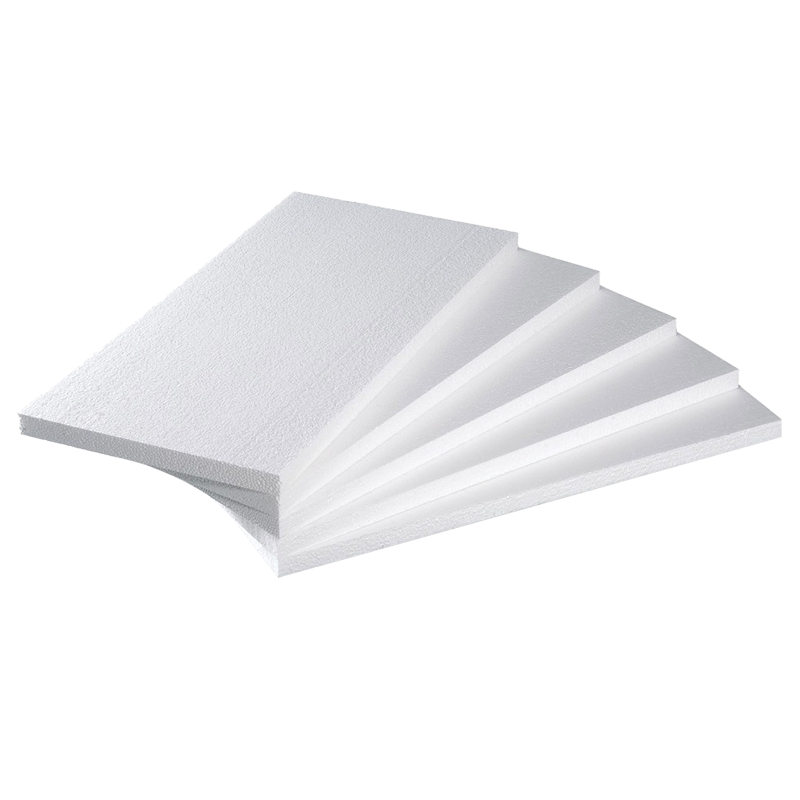

Function: Polypropylene resin is the base material of FR-MPP Foam Sheet, which provides the main structure and basic properties of the material. Polypropylene has excellent mechanical properties, chemical stability and processing properties, and is an ideal choice for manufacturing microporous polypropylene foam sheets.

Supply: Polypropylene resin is one of the plastics widely produced and used worldwide, and its supply is relatively sufficient and stable. There are many large petrochemical companies in the world, such as ExxonMobil, BASF, Sinopec, etc. These companies have strong production capacity and technical strength, and can stably supply high-quality polypropylene resin. In addition, with the continuous advancement of polypropylene production technology and the gradual expansion of production capacity, its price is relatively stable, which is conducive to the production cost control of FR-MPP Foam Sheet.

Flame retardant

Function: Flame retardant is a key additive that gives FR-MPP Foam Sheet flame retardant properties. By adding an appropriate amount of flame retardant, the flame propagation speed, combustion heat release rate and smoke release can be slowed down when the material burns, thereby improving the fire safety of the material.

Supply: There are many types of flame retardants, including inorganic flame retardants (such as magnesium hydroxide, aluminum hydroxide, etc.) and organic flame retardants (such as bromine flame retardants, phosphorus flame retardants, etc.). The supply of these flame retardants varies depending on the type and market demand. Generally speaking, large chemical companies and professional flame retardant manufacturers are able to stably supply various flame retardants to meet the needs of FR-MPP Foam Sheet production. However, it should be noted that with the increasingly stringent environmental regulations, the environmental performance requirements for flame retardants are also getting higher and higher, so the supply of environmentally friendly flame retardants may be affected to a certain extent.

Other additives

Function: In addition to polypropylene resin and flame retardant, a series of additives need to be added in the production process of FR-MPP Foam Sheet, such as foaming agent, nucleating agent, crosslinking agent, plasticizer, etc. These additives play an important role in material processing and performance regulation, and can improve the foaming performance of materials, improve the strength and toughness of materials, etc.

Supply: The supply of these additives is also relatively stable, but the specific supply volume and price may vary due to factors such as market demand and raw material costs. Generally speaking, professional chemical manufacturers and additive suppliers can stably supply various additives to meet the needs of FR-MPP Foam Sheet production.

The main raw materials for the production of FR-MPP Foam Sheet include polypropylene resin, flame retardant and other additives. The supply of these raw materials is relatively stable, but the price may be affected by various factors such as market demand, raw material costs, and environmental regulations. In order to ensure the stability of production and the effectiveness of cost control, FR-MPP Foam Sheet manufacturers need to pay close attention to market trends and raw material supply, establish long-term and stable cooperative relationships with suppliers, and continuously optimize production processes and formulas to improve product competitiveness and added value. At the same time, with the continuous development of new material technology and the continuous expansion of application fields, the production technology and raw materials of FR-MPP Foam Sheet will also be continuously updated and optimized to meet the market demand for high-performance and environmentally friendly materials.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229