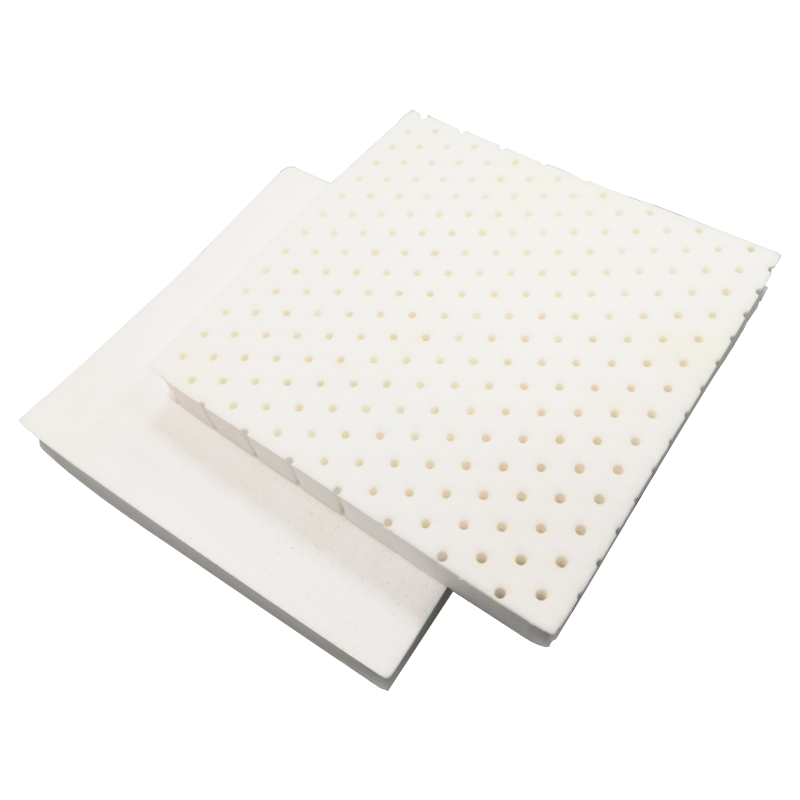

Do you know MPP Foam Sheet? So do you know what MPP refers to? Today I will simply introduce it to you. New Microcellular Polypropylene Foaming Material, MPP for short, refers to polypropylene porous foaming material with cell size less than 100 microns (more strictly defined as cell size less than 10 microns and cell density greater than 10 to the 9th power) pieces/cm3). Due to the existence of a large number of micron-sized cells inside the material, MPP has excellent shock absorption, cushioning, heat insulation, and sound absorption properties, and can be widely used in packaging, transportation, luggage, and sports equipment, and other fields. The best alternative to PS foam, EPE, and EPP.

performance and application

MPP was prepared by supercritical carbon dioxide technology, carbon dioxide gas was introduced into the polypropylene material matrix under high temperature and high pressure, and its nucleation and foaming were induced to form a microcellular foamed material containing a large number of micron-scale cells. The foaming process is clean and pollution-free, and the foamed products are hygienic and environmentally friendly. The PP material is not cross-linked during the foaming process, so it can be recycled and reused.

Polypropylene (PP) itself is a non-toxic material and is currently a commonly used material for baby bottles and microwaveable lunch boxes. The clean and hygienic MPP is especially suitable for fields with high hygienic grade requirements for packaging materials such as medical equipment and food. It can also be used in children's puzzles, toys, and other fields with high product health requirements, instead of the commonly used cross-linked PE foam and EVA foam made of AC foaming agent.

PP is a semi-crystalline polymer, its melting point is generally 150~170℃. Compared with PE, PS, and PU foam materials with a temperature resistance of only 70~80°C, the operating temperature of MPP can reach 120°C, so MPP is especially suitable for high-temperature packaging, and high-temperature insulation and other fields.

MPP integrates enhancement, heat insulation, and noise reduction, and is especially suitable for fields with high requirements for lightweight materials, such as automobiles, rail transit, ships, fan blades, etc.

Lightweight and high-strength MPP slabs are used as structural foams to replace traditional structural foams such as PVC/PU interpenetrating structural foams, PET structural foams, etc., especially as the core material of sandwich composite materials.

I hope this content is helpful to you. If you want to know more, please continue to follow us! Shincell is a professional lightweight foam material manufacturer.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229