Home / News / What should we pay attention to during the processing of MPP Foam Sheet?

1. Understanding material properties

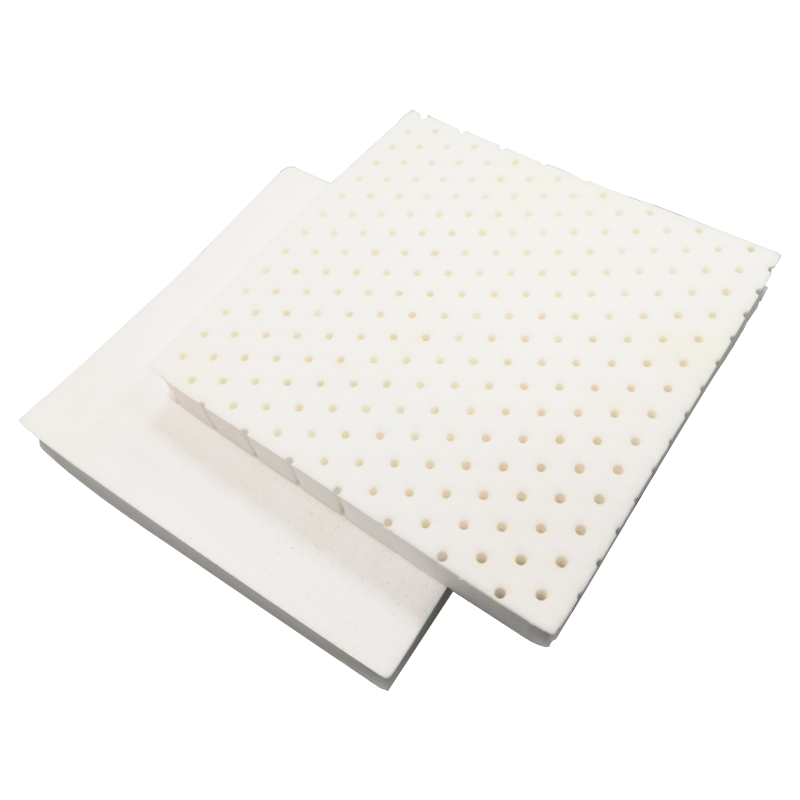

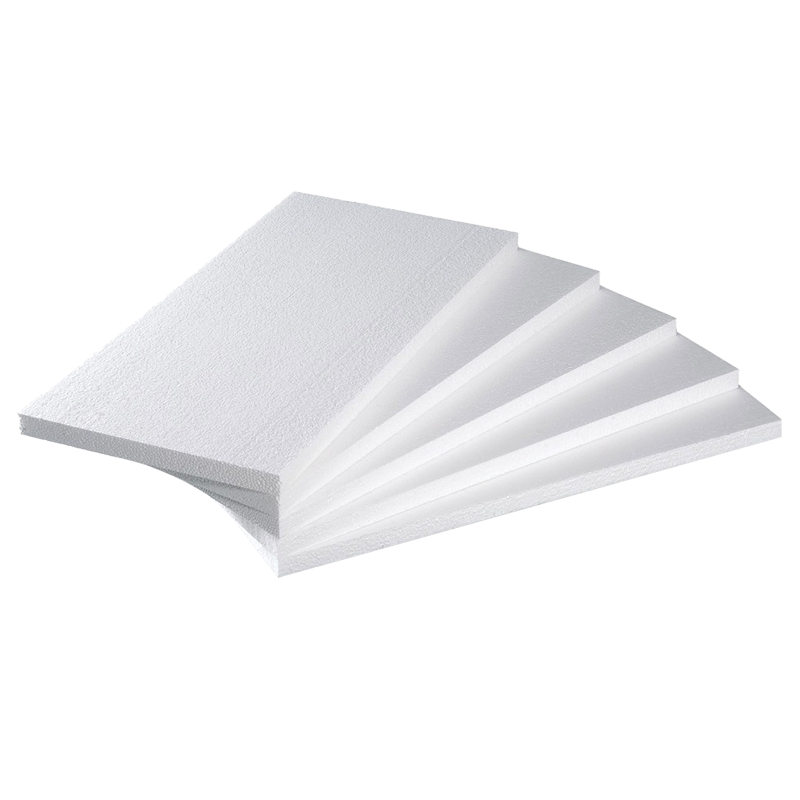

MPP Foam Sheet has the characteristics of light weight, high strength, thermal insulation, etc., but it also has a certain degree of brittleness. Therefore, it is necessary to fully understand the characteristics of the material before processing. Understand the density, thickness, strength and other parameters of MPP Foam Sheet so that you can choose appropriate cutting speed, tool angle and other parameters during processing to avoid material fragmentation or excessive burrs.

2. Selection of processing equipment

Heating wire cutting machine: suitable for cutting large areas, straight lines or simple graphics. It has fast cutting speed, simple operation and relatively low cost. However, it should be noted that electric heating wire cutting may produce a certain heat-affected zone, which will have a certain impact on material properties.

Laser cutting machine: suitable for cutting high-precision, complex graphics. Laser cutting has the advantages of high cutting accuracy, fast speed, and small heat-affected zone, but the equipment cost is high and requires professional operation and maintenance.

Mechanical cutting machine: suitable for cutting small and medium-sized areas and mass production. Mechanical cutting machines can achieve cutting by rotating or moving the cutter, which is simple to operate and moderate in cost. But you need to choose the right tool to ensure cutting quality and efficiency.

In addition to the main cutting equipment, some auxiliary equipment and tools also need to be considered, such as positioning devices, clamps, vacuum cleaners, etc. These equipment and tools can help improve processing accuracy and efficiency, and reduce operating difficulty and labor intensity. When selecting processing equipment, in addition to considering the performance and functionality of the equipment, you also need to pay attention to the stability and durability of the equipment. Stable equipment can ensure the continuity and consistency of the processing process, while durable equipment can reduce the frequency of repairs and replacements, reducing production costs.

3. Tool selection and maintenance

Tool selection and maintenance are crucial for MPP Foam Sheet processing. The appropriate tool should be selected according to the thickness and hardness of the material, and the tool must be sharp to reduce cutting resistance and heat generation. At the same time, the cutting tools should be cleaned and maintained regularly to avoid tool wear or clogging that affects the processing quality.

4. Processing environment control

The processing environment of MPP Foam Sheet should be kept dry and clean to avoid dust and moisture contaminating the material. At the same time, the temperature should be controlled during processing to avoid excessively high or low temperatures affecting material properties. In addition, attention should be paid to ventilation to reduce the harm to the human body caused by harmful gases generated during processing.

5. Processing technology optimization

The optimization of processing technology is the key to improving the processing efficiency and quality of MPP Foam Sheet. During the processing, appropriate processing techniques and parameters should be selected based on the characteristics of the material and processing requirements. For example, for complex graphic cutting, high-precision processing methods such as laser cutting or CNC cutting can be used; for large-volume production, automated production lines can be used for processing to improve production efficiency.

6. Quality control and inspection

Quality control and inspection are important links to ensure the processing quality of MPP Foam Sheet. During the processing process, the size, appearance and other aspects of the processed parts should be inspected regularly to ensure that they meet quality requirements. At the same time, various parameters during the processing should also be monitored and adjusted to ensure the stability of processing quality.

7. Safe operation

Safe operation is an aspect that cannot be ignored during MPP Foam Sheet processing. During processing, safe operating procedures should be followed and protective equipment should be worn to avoid accidental injuries. At the same time, attention should also be paid to the maintenance and upkeep of the equipment to ensure the safe operation of the equipment.

English

English

Español

Español

++86-0512-66079229

++86-0512-66079229